Pat Anderson

New member

- Joined

- Nov 2, 2003

- Messages

- 8,562

- Reaction score

- 0

- C Dory Year

- 2005

- C Dory Model

- 25 Cruiser

- Vessel Name

- Daydream

It is important to share when you get good service - like Pete at West Coast Marine , Jesse at Bitter End Boatworks and Jim at Sterling Kayaks and Fiberglass. Now another one to add to the list - Devon and Kevin from PetroClean, which is a mobile fuel polishing service! They mostly do diesel of course but can also deal with water in gas, which was my problem.

At the end of August last year, I had a medical emergency at James Island (Dan and Tanya know the gory details, I won't go into them here) and we needed to boogie back to Bellingham as fast as we could. We are normally 6-7 knot cruisers, but we had the pedal to the metal on the way back, and that apparently mixed the water in the tank with the gas - we made it back but at home when I went to flush the engine, the big Racor fuel-water separator was completely full of water, no fuel visible at all.

So we knew we needed to deal, once again, with the water in the fuel tank. I got a recommendation for PetroClean from Pete at West Coast Marine. Devon and Kevin from PetroClean just left about an hour ago, I was really impressed with their service! Here is kind of a blow by blow:

First, they removed the fuel gauge sender unit and pumped all the gas out of the tank through the fuel gauge sender hole, and filtered it into big drums - the good gas into one and the water and gas into another waste drum. They ended up with about 50 gallons of good gas.

Next they put about 10 gallons of diesel into the tank so there would not be volatile fumes that might explode.

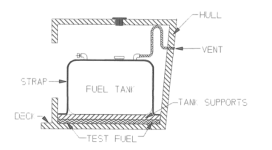

Then they cut an access port into the top of the tank next to the fuel gauge sender hole, here is a pic:

Then they vacuumed out the fuel tank, and hand cleaned it with absorbent paper. They actually did this before they put the access port hardware on. I looked in and the tank was absolutely clean and shiny. Devon said the tank was actually in very good condition, which was reassuring since more than a few CD25 fuel tanks have failed!

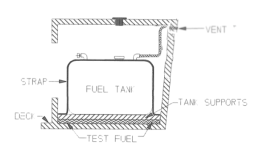

Then they pumped the good gas back in, again through a water separating filter. Finally, they fit the cover on the access port, here is a pic with the cover on:

The little inspection port in the cockpit floor was never over the fuel gauge sender unit, and they recommended that I put a larger hatch cover over both the fuel gauge sender unit and my nifty new access port, so if I ever needed the fuel tank cleaned again, it would be quick and easy. That will be my next project before I put the cockpit floor back down and re-caulk.

PetroClean charges $100 an hour with a four hour minimum plus parts, so the total ding was $672, which was well worth it for my peace of mind! It took them a little over two and a half hours. They also disposed of the WAY old gas in the tanks of the CD16 Crabby Lou for no additional charge.

I also got a good look at the inside of a CD25 100 gallon fuel tank and the pick-up tubes, which are actually a couple of inches above the bottom of the tank.

We will now fill the tank with non-ethanol gas with Stabil. Their advice was for a boat that is used every season to keep the tank full, and only empty the tank if a boat is going into prolonged storage. I know there are different opinions about this, but this is what I plan to do, no more off-seasons with a half empty tank!

So, hope you don't, but if you need to deal with water in your fuel tank, these are the guys!

At the end of August last year, I had a medical emergency at James Island (Dan and Tanya know the gory details, I won't go into them here) and we needed to boogie back to Bellingham as fast as we could. We are normally 6-7 knot cruisers, but we had the pedal to the metal on the way back, and that apparently mixed the water in the tank with the gas - we made it back but at home when I went to flush the engine, the big Racor fuel-water separator was completely full of water, no fuel visible at all.

So we knew we needed to deal, once again, with the water in the fuel tank. I got a recommendation for PetroClean from Pete at West Coast Marine. Devon and Kevin from PetroClean just left about an hour ago, I was really impressed with their service! Here is kind of a blow by blow:

First, they removed the fuel gauge sender unit and pumped all the gas out of the tank through the fuel gauge sender hole, and filtered it into big drums - the good gas into one and the water and gas into another waste drum. They ended up with about 50 gallons of good gas.

Next they put about 10 gallons of diesel into the tank so there would not be volatile fumes that might explode.

Then they cut an access port into the top of the tank next to the fuel gauge sender hole, here is a pic:

Then they vacuumed out the fuel tank, and hand cleaned it with absorbent paper. They actually did this before they put the access port hardware on. I looked in and the tank was absolutely clean and shiny. Devon said the tank was actually in very good condition, which was reassuring since more than a few CD25 fuel tanks have failed!

Then they pumped the good gas back in, again through a water separating filter. Finally, they fit the cover on the access port, here is a pic with the cover on:

The little inspection port in the cockpit floor was never over the fuel gauge sender unit, and they recommended that I put a larger hatch cover over both the fuel gauge sender unit and my nifty new access port, so if I ever needed the fuel tank cleaned again, it would be quick and easy. That will be my next project before I put the cockpit floor back down and re-caulk.

PetroClean charges $100 an hour with a four hour minimum plus parts, so the total ding was $672, which was well worth it for my peace of mind! It took them a little over two and a half hours. They also disposed of the WAY old gas in the tanks of the CD16 Crabby Lou for no additional charge.

I also got a good look at the inside of a CD25 100 gallon fuel tank and the pick-up tubes, which are actually a couple of inches above the bottom of the tank.

We will now fill the tank with non-ethanol gas with Stabil. Their advice was for a boat that is used every season to keep the tank full, and only empty the tank if a boat is going into prolonged storage. I know there are different opinions about this, but this is what I plan to do, no more off-seasons with a half empty tank!

So, hope you don't, but if you need to deal with water in your fuel tank, these are the guys!