Hi folks,

So, I bought two of the Johnson "Ultima" 600 gph bilge pumps, one for the "sump" near the transom drain plug, and the other for the "side bilge sump" that is between the galley and the cockpit on my era 22 Cruiser (2002).

Because of the shape of the hull, this "side bilge sump" is angled athwartships. This didn't really concern me until I sat down to read the pump instructions and they specified that the pump should be level on the exact plane where my hull slopes there. I had planned to install it with the outlet elbow facing outboard, which would make for an angled pump, not a level one.

Now, that being said, there are a few other things in the instructions that I'm not following, but on those I'm comfortable with it because I understand why they are saying what they are saying, and also why I'm not doing what they say (mounting it on a 3/4" piece of plywood, screwing it into the hull, etc.).

I could level the pump on a wedge, of course, but I really don't want to unless I have to. If I understood why they are requesting it to be level, then I could figure out for myself if I need to adhere to the letter of the law, or merely the spirit of it, and/or what I would be giving up if I ignored it altogether.

This is the style of pump that has two sensor pads on one end, and the discharge on the other end (i.e. a built-in switch). I suspect it has something to do with that but I don't understand it enough to figure out what it is.

[Edit: In thinking about this more, I think I can maybe see why it shouldn't be mounted in *one* of the un-level dimensions. Maybe if the sensor pads were "down" (how I was going to mount it, actually), then they would be in that last little bit of water and telling the impeller to pump water out, but the impeller would be "high and dry" and so there would be an endless loop of dry pumping. On the other hand, that only explains why the sensors should not be low, and doesn't cover the other three ways for the pump be un-level, which are also not recommended. You'd think if that were the case they would say "don't mount pump with sensors below impeller." Argh, why can't they just explain the basic concept for those of us who would like to better understand it :amgry (btw, I did check the website but didn't see anything helpful).]

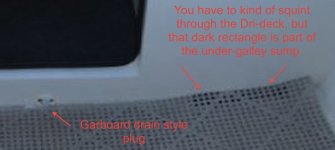

Here is a photo of the pump with my notes:

Thanks to anyone who can help me to understand this,

Sunbeam :hot

So, I bought two of the Johnson "Ultima" 600 gph bilge pumps, one for the "sump" near the transom drain plug, and the other for the "side bilge sump" that is between the galley and the cockpit on my era 22 Cruiser (2002).

Because of the shape of the hull, this "side bilge sump" is angled athwartships. This didn't really concern me until I sat down to read the pump instructions and they specified that the pump should be level on the exact plane where my hull slopes there. I had planned to install it with the outlet elbow facing outboard, which would make for an angled pump, not a level one.

Now, that being said, there are a few other things in the instructions that I'm not following, but on those I'm comfortable with it because I understand why they are saying what they are saying, and also why I'm not doing what they say (mounting it on a 3/4" piece of plywood, screwing it into the hull, etc.).

I could level the pump on a wedge, of course, but I really don't want to unless I have to. If I understood why they are requesting it to be level, then I could figure out for myself if I need to adhere to the letter of the law, or merely the spirit of it, and/or what I would be giving up if I ignored it altogether.

This is the style of pump that has two sensor pads on one end, and the discharge on the other end (i.e. a built-in switch). I suspect it has something to do with that but I don't understand it enough to figure out what it is.

[Edit: In thinking about this more, I think I can maybe see why it shouldn't be mounted in *one* of the un-level dimensions. Maybe if the sensor pads were "down" (how I was going to mount it, actually), then they would be in that last little bit of water and telling the impeller to pump water out, but the impeller would be "high and dry" and so there would be an endless loop of dry pumping. On the other hand, that only explains why the sensors should not be low, and doesn't cover the other three ways for the pump be un-level, which are also not recommended. You'd think if that were the case they would say "don't mount pump with sensors below impeller." Argh, why can't they just explain the basic concept for those of us who would like to better understand it :amgry (btw, I did check the website but didn't see anything helpful).]

Here is a photo of the pump with my notes:

Thanks to anyone who can help me to understand this,

Sunbeam :hot