I posted some last year about my issue with water intrusion into the enclosed seating area on the aft of my 1983 16' Angler. I finally got that project completed and now have some nice, open storage bins under the seat. As I was closing in on the final touches I noticed two small screw holes in the floor of the cockpit, a couple of inches forward of where the vertical portion of the seat meets it. I was doing some minor glass work repairing other screw holes on the deck so I took a reaming tool and started to grind off the old material and get down to some clean glass and wood so I could put down a decent patch or plug. To my surprise the bit plunged right on through the upper layer of fiberglass, as whatever was underneath (balsa?) had rotted away. The boat has been stored indoors for about eight months but there were signs of moisture in the punky wood fibers that I retrieved through the small opening. I'm wondering what's my next move is? Is that balsa wood under there? The floor of the cockpit feels solid as a rock. What's under there? I thought I was going boating next week

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thought I had 'er licked.

- Thread starter hoorenga

- Start date

I am not familiar with the 16, but all of the C Dorys have cored bottoms until about the area where the "V" is in the forward 1/3 of the boat--from there forward it is solid glass.

Based on what you have noted, I would start reaming out the area where you found the wet core. Drilling small holes to see what it is like will work--going only a short distance at a time. Most likely the core moisture intrusion is only a small area. You can fill this with thickened epoxy and go on about your way.

Based on what you have noted, I would start reaming out the area where you found the wet core. Drilling small holes to see what it is like will work--going only a short distance at a time. Most likely the core moisture intrusion is only a small area. You can fill this with thickened epoxy and go on about your way.

Thanks for the tip Bob. I did as you said and drilled four pilot holes about four inches away from the old screw holes in four different directions. The material that I found underneath was dry and looked like it could be balsa wood. It was a light color and soft. I didn't detect any moisture. Thank you Jesus! (and Bob). Should I be worried about the area where there was rot and moisture? Do I need to make a bigger hole and clean it out? How big of a hole do I make?

Doug

Doug

I think I remember reading that the older ("classic" boats had a plywood core in the bottom, but I'm not sure, plus that might not be the 16 anyway. But, it doesn't matter that much. I'd bet dollars to doughnuts it's *some* kind of wood coring, and what you describe is a classic scenario of saturated/rotted core, as can easily happen around a fastener hole. It does sound like balsa from what you describe (my 22 also has balsa in the bottom).

The fact that you took core samples 4" out that are dry is great. Whew! Here is what I would do now (there is some variation in how different people handle these things, and more than one right answer).

1) I would want to get all the wet coring out. Now, it may not be easily possible, and the plan might change, but that would be my initial goal.

2) There is no "hard line" on this, but essentially up to a certain size hole you can just fill with thickened epoxy; past a certain diameter you would want to finish with a circle of fiberglass (over the thickened epoxy). I'd put the "line" at around 1/2" or maybe a bit more.

3) I would start by going into the holes you have and seeing how far back you can dig, and if you can get to dry core. If so, great. If not, I would drill bigger holes. You can get creative about reaching in to dig out core. I have had great luck with a dental pick, but also use a Dremel #115 bit at times, or other Dremel bits (pick is quiet and not as dusty). I had some wet core around fuel tank cleat fasteners. In the biggest spot (about the diameter of a 50 cent piece), I drilled something like a 1/2" hole and dug from there and was able to get to dry core all around. It is possible to cut as large a hole as you need to, but anything much larger you would want to patch with fiberglass, to my mind.

4) Once you have all the wet stuff out, you can fill, which will also seal the core there from new moisture. I've become fond of the WEST 610 now, but used "home brew" thickened epoxy for years too. At any rate, you first soak the area with "neat" epoxy (I either paint it on, or inject it with a syringe, let it soak, and then suck it back out), and then you go back in with thickened (colloidal silica or structural filler) and fill the hole completely. If needed, then you can glass over the top.

5) Additional notes:

-- I usually chamfer the top of the hole a bit for more contact area.

-- Make sure to solvent wash or otherwise remove dust and etc. between operations.

-- If you keep the epoxy in the green stage (easily dentable), you can just do it all without having to sand or wash between layers. If it hardens past that stage, you have to start from scratch with washing, sanding, etc. (window for chemical bond is then gone and you have to get a mechanical bond).

-- No matter how big your holes are, undercut the balsa a bit so that you have a "hook" rim on the underside of the top fiberglass skin (vs. just a smooth wall all the way up, if that makes sense).

-- With a blind hole (i.e. no outlet on the bottom) you will have trouble filling without trapping air if you fill from the top. If you can, use a syringe maybe with a straw or small shrink tubing and start filling from the bottom and going up (or connect two holes so you can do it like a lower unit).

-- Taping around everything and being tidy is a lot easier than cleaning up otherwise. I tape over the whole shebang and then use an Exacto knife to cut out the hole area.

-- If you don three or more disposable gloves when starting, then you can just a dirty one off to reveal a fresh one without getting your skin epoxied (you can get sensitized).

The fact that you took core samples 4" out that are dry is great. Whew! Here is what I would do now (there is some variation in how different people handle these things, and more than one right answer).

1) I would want to get all the wet coring out. Now, it may not be easily possible, and the plan might change, but that would be my initial goal.

2) There is no "hard line" on this, but essentially up to a certain size hole you can just fill with thickened epoxy; past a certain diameter you would want to finish with a circle of fiberglass (over the thickened epoxy). I'd put the "line" at around 1/2" or maybe a bit more.

3) I would start by going into the holes you have and seeing how far back you can dig, and if you can get to dry core. If so, great. If not, I would drill bigger holes. You can get creative about reaching in to dig out core. I have had great luck with a dental pick, but also use a Dremel #115 bit at times, or other Dremel bits (pick is quiet and not as dusty). I had some wet core around fuel tank cleat fasteners. In the biggest spot (about the diameter of a 50 cent piece), I drilled something like a 1/2" hole and dug from there and was able to get to dry core all around. It is possible to cut as large a hole as you need to, but anything much larger you would want to patch with fiberglass, to my mind.

4) Once you have all the wet stuff out, you can fill, which will also seal the core there from new moisture. I've become fond of the WEST 610 now, but used "home brew" thickened epoxy for years too. At any rate, you first soak the area with "neat" epoxy (I either paint it on, or inject it with a syringe, let it soak, and then suck it back out), and then you go back in with thickened (colloidal silica or structural filler) and fill the hole completely. If needed, then you can glass over the top.

5) Additional notes:

-- I usually chamfer the top of the hole a bit for more contact area.

-- Make sure to solvent wash or otherwise remove dust and etc. between operations.

-- If you keep the epoxy in the green stage (easily dentable), you can just do it all without having to sand or wash between layers. If it hardens past that stage, you have to start from scratch with washing, sanding, etc. (window for chemical bond is then gone and you have to get a mechanical bond).

-- No matter how big your holes are, undercut the balsa a bit so that you have a "hook" rim on the underside of the top fiberglass skin (vs. just a smooth wall all the way up, if that makes sense).

-- With a blind hole (i.e. no outlet on the bottom) you will have trouble filling without trapping air if you fill from the top. If you can, use a syringe maybe with a straw or small shrink tubing and start filling from the bottom and going up (or connect two holes so you can do it like a lower unit).

-- Taping around everything and being tidy is a lot easier than cleaning up otherwise. I tape over the whole shebang and then use an Exacto knife to cut out the hole area.

-- If you don three or more disposable gloves when starting, then you can just a dirty one off to reveal a fresh one without getting your skin epoxied (you can get sensitized).

Thanks Sunbeam. I now have a plan. That's a whole heck of a lot more than I what had this morning. I was really bummed. I was imagining the whole inside of the hull being rotten. I may get her in the water yet this Summer. I promise some photos when it's all back together. I was really tickled with what I ended up using to trim the cut outs under the transom seat with. It was a white, polyurethane material designed for outdoor use on homes that was a one inch right angle piece about three eights of an inch thick. I cut it like a picture frame and screwed and epoxied it around the openings.

Oh, one thing I forgot to mention:

Epoxy gets hot as it cures, and this can be bad (can actually catch on fire, can foam/bubble out, and/or just not make as strong a mix). It depends on weather (hotter weather/hotter cure), the type of hardener (fast hardener will go of faster/hotter if it is hot out) and size of the fill (more epoxy gets hotter than a small amount).

There are a few ways to deal with this:

1) Fill in stages (not going past the green stage so you don't have to prep for next fill) so that you are not filling a huge area all in one go.

2) Slower hardener

3) Keep epoxy cool (this is really more of a help with keeping it from kicking as you are working). Keeping it spread out helps too, vs. a deep cup that concentrates it.

4) If you have an infrared thermometer you can keep an eye on it as it kicks, which is nice for developing a sense of how it's going.

5) If it starts to foam and bubble out of the hole, I would dig it out and start over, as it will probably get too foamy and weaker.

6) Always have a place in mind to toss an "epoxy bomb" (bare ground, concrete, etc.) --- that is, a cup of epoxy you are working with that starts to smoke.

7) Once it starts to kick don't keep using it (always tempting), but rather make another batch.

Would love to see photos of what you have accomplished. You'll feel great once you have the bad stuff out and the repair made :thup

Epoxy gets hot as it cures, and this can be bad (can actually catch on fire, can foam/bubble out, and/or just not make as strong a mix). It depends on weather (hotter weather/hotter cure), the type of hardener (fast hardener will go of faster/hotter if it is hot out) and size of the fill (more epoxy gets hotter than a small amount).

There are a few ways to deal with this:

1) Fill in stages (not going past the green stage so you don't have to prep for next fill) so that you are not filling a huge area all in one go.

2) Slower hardener

3) Keep epoxy cool (this is really more of a help with keeping it from kicking as you are working). Keeping it spread out helps too, vs. a deep cup that concentrates it.

4) If you have an infrared thermometer you can keep an eye on it as it kicks, which is nice for developing a sense of how it's going.

5) If it starts to foam and bubble out of the hole, I would dig it out and start over, as it will probably get too foamy and weaker.

6) Always have a place in mind to toss an "epoxy bomb" (bare ground, concrete, etc.) --- that is, a cup of epoxy you are working with that starts to smoke.

7) Once it starts to kick don't keep using it (always tempting), but rather make another batch.

Would love to see photos of what you have accomplished. You'll feel great once you have the bad stuff out and the repair made :thup

Sunbeam":1vwctdyz said:I think I remember reading that the older ("classic" boats had a plywood core in the bottom, but I'm not sure, plus that might not be the 16 anyway. But, it doesn't matter that much. <MUCH DELETED>

Just a point of clarification:

The older "Classic: C-Dorys with the plywood core bottom were the early 22's (up through 1986) with the flat bottoms all the way aft, which allowed for the use of flat plywood sheets for a core instead of the more recently used balsa/scrim made up of small balsa squares and fiberglass cloth that is flexible and fits into curved molds.

The change in the hull shape in 1987 necessitated a switch to the later type core.

I'm not sure, but I think I remember someone saying the plywood sheet was 1" thick. I've never seen a layup of a Classic hull in progress.

Joe. :teeth :thup

hoorenga":21o9w86q said:So what do I have under the deck if it is an 82, 16 foot Angler? I'm thinking it's balsa wood? Is it a balsa wood sandwich? Meaning is it fiberglass on the outside and nothing but balsa wood on the inside? Just trying to get a visual of what is behind the curtain.

I don't know specifically how your boat would have been constructed, but in general, the reason cored construction is used is because it makes a relatively light, stiff panel. What makes it work is the tensile strength of the "sandwich" of the three layers bonded together - works sort of like an I-beam. This is why it's important that they stay bonded (otherwise you have three, floppy boats instead of one stiff one). My 22 has a cored bottom (mostly), cored decks, and also some cored cabinside areas and interior panels. There may be some cored roof as well, I don't know yet.

Thus, typical cored construction is a sandwich of *fiberglass laminate/core (wood, foam, honeycombed plastic, etc./fiberglass laminate* Typically the fiberglass is relatively thin as compared to the core. I would guess your core is plywood or vertical-grained balsa (I've seen some older sailboats with balsa laid in as planks, but I'm guessing not your 16). Balsa comes out (when dry) very light colored, like you'd picture birch say, and with a fine vertical fibery "grain." Let me see if I can dig up a photo from one of my projects and post it back. I haven't ever dug out plywood core, but I can't imagine it would "pick out" in the same characteristic way as balsa.

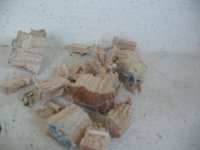

Edited to add: Okay, here are some photos of balsa core from my boat. These are dry bits. When damp it can look the same but just slightly darker in color (if you squeeze it your fingers would end up moist), and when really wet/rotten can go all the way to black soup.

This is some dry balsa core I removed from the bottom in the transom/sump area. Because it was dry, I had to work to get it de-bonded from the bottom fiberglass skin. Wet core will usually come off easily (not good).

This balsa "core sample" is one I drilled out of the transom while prepping to mount a Mini Jacker kicker mount. After this I cut out more core ("back cut") with the Dremel #115 bit and then filled the works with thickened epoxy before re-drilling the fastener hole in the center. You can see the outer fiberglass skin at the top of the plug. The blue on the very top is blue tape. There is no fiberglass skin showing on the bottom because that's still on my boat - it's the inner layer of the transom which stays as-is (just gets a small hole equal to the diameter of the fastener, so that gets turned to powder by the drill bit).

Sunbeam

I'm some what familiar with boat work, from glass to plywood. What came out as dry wood when I drilled the test holes is very similar to your balsa wood core photos. I'm certain that's what it is. Thanks again, it's nice to have all of this information so I can have a visual in my mind of what I can't see with my eyes. I'm feeling very confident. Let's hope that feeling keeps rolling along.

At this point I would "sound" the first hole--after drilling it out to about 3/8 to 1/2". At that point you can use an ice pick and see if about how far out the wet core extends. It may not be much more than the 1/2 to one inch. Route this out, fill with thickened epoxy. I would agree with a circle of glass over the area, if the hole is over 1/2". For thickening, I use Cabosil (Fumed silica) and one of the filler materials--I happen to use West System and for a bottom like this I would probably use High density filler. With a horizontal surface it can be a little more Liquid than if a vertical surface you are filling.

I think that Sunbeam's suggestion of the Six 10 metered filler will be cheaper and easier. You can buy some smaller amount of epoxy to do the pre coating with.

As for the heat issue; if you select the catalyst and condition of working with it that should not be a problem. Generally in the PNW it is cool enough to aovid that, and you will not be mixing large amounts of material.

I would also fill the drilled holes with epoxy--work it down in first.

Keep us all abreast of the work--and you should be back on the water in short order. Good work!

I think that Sunbeam's suggestion of the Six 10 metered filler will be cheaper and easier. You can buy some smaller amount of epoxy to do the pre coating with.

As for the heat issue; if you select the catalyst and condition of working with it that should not be a problem. Generally in the PNW it is cool enough to aovid that, and you will not be mixing large amounts of material.

I would also fill the drilled holes with epoxy--work it down in first.

Keep us all abreast of the work--and you should be back on the water in short order. Good work!

One note on the WEST 610: They say it is thin enough to wet out holes with (as opposed to using neat epoxy). I have no reason not to believe them, but for myself, on "critical" holes (below the waterline, transom, etc.) I still used regular neat epoxy for that.

Would be interesting to do some tests on 610 wet out vs. regular.

Sunbeam

Would be interesting to do some tests on 610 wet out vs. regular.

Sunbeam