Tug,

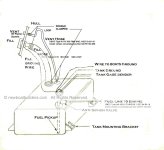

Yes, on the wiring of the gauge. Larry of course is correct on the proper point of grounding.

The reasons that I brought up the tank fill and venting issue is that it is direct violation of ABYC H24.13.1 and H-24.17.2, Which state a fuel fill must be located where any overflow would run down a walkway or gunnel and out a drain, not entering the cockpit. There is also language that the vent must be outside of the cockpit. It isn't just an issue of smoking--it is of use of any non ignition protected equipment in the cabin or cockpit. I understand that you are careful and use a funnel, but there are significant risks.

I suspect that there are insurance implications if you were to ever have a fire or explosion aboard.

There are also regs in CFR title 33 Sub Section J such as:

Sec. 183.520 Fuel tank vent systems.

(a) Each fuel tank must have a vent system that prevents pressure in the tank from exceeding 80 percent of the pressure marked on the tank label under Sec. 183.514(b)(5).

(b) Each vent must:

(1) Have a flame arrester that can be cleaned unless the vent is itself a flame arrestor; and

(2) Not allow a fuel overflow at the rate of up to two gallons per minute to enter the boat.

Sec. 183.550 Fuel tanks: Installation.

"e) Each fuel tank support, chock, or strap that is not integral with a metallic fuel tank must be insulated from the tank surface by a non-moisture absorbing material."

Sec. 183.564 Fuel tank fill system.

(a) Each fuel fill opening must be located so that a gasoline overflow of up to five gallons per minute for at least five seconds will not enter the boat when the boat is in its static floating position.

(b) Each hose in the tank fill system must be secured to a pipe, spud, or hose fitting by:

(1) A swaged sleeve;

(2) A sleeve and threaded insert; or

(3) Two adjacent metallic hose clamps that do not depend solely on the spring tension of the clamps for compressive force.

(c) Each hose clamp in the tank fill system must be used with a hose designed for clamps.

(d) Hose clamps used in the tank fill system must:

(1) Have a minimum nominal band width of at least one-half inch; and

(2) Be over the hose and the spud, pipe, or hose fitting."