kcohen4

New member

- Joined

- Oct 26, 2020

- Messages

- 50

- Reaction score

- 0

- C Dory Year

- 2004

- C Dory Model

- 16 Cruiser

- Hull Identification Number

- CD016486B404

- Vessel Name

- Annie M.

Since I can't go anywhere I just keep on making projects for the Annie M.

Clean, Clean and Clean.

New SeaDek Floor

Redo the wiring, tired of the birds nest behind the panel

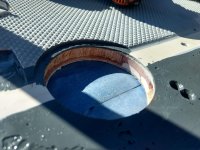

Added Volt meter. had a 2" hole anyway from when the boat had a Honda

Added ICOM M330G with antenna

Got my MMSI Number

Added Racor gas Filter

Got nice burgundy covers for the bumpers

Put electric winch on the trailer

New nice looking White Wheels and new tires for the trailer

New Battery just to be safe.

Varnished the teak on the table with 8 coats.

All this on a 16ft Cruiser.

Yes really bored. Hope I can get shot so I can put the boat in the water this coming summer!!

Ken

Clean, Clean and Clean.

New SeaDek Floor

Redo the wiring, tired of the birds nest behind the panel

Added Volt meter. had a 2" hole anyway from when the boat had a Honda

Added ICOM M330G with antenna

Got my MMSI Number

Added Racor gas Filter

Got nice burgundy covers for the bumpers

Put electric winch on the trailer

New nice looking White Wheels and new tires for the trailer

New Battery just to be safe.

Varnished the teak on the table with 8 coats.

All this on a 16ft Cruiser.

Yes really bored. Hope I can get shot so I can put the boat in the water this coming summer!!

Ken